| Availability: | |

|---|---|

| Quantity: | |

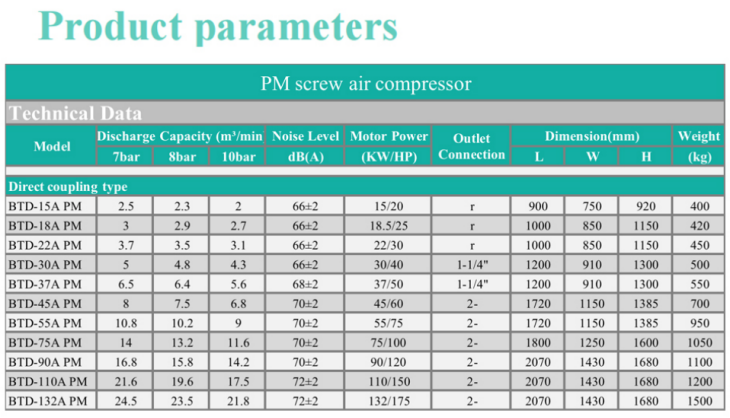

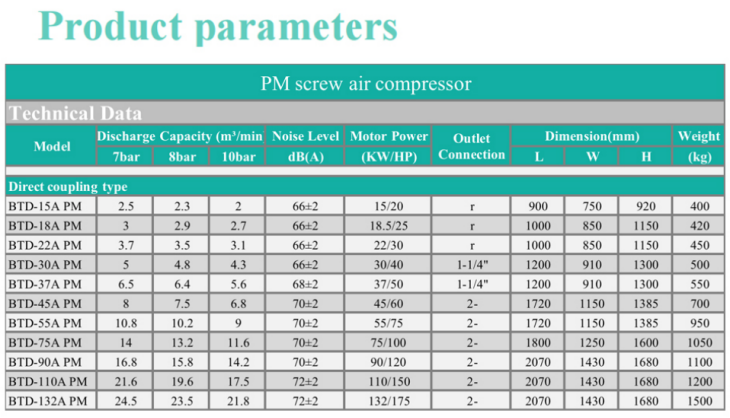

Permanent Magnet Inverter Screw Air Compressor

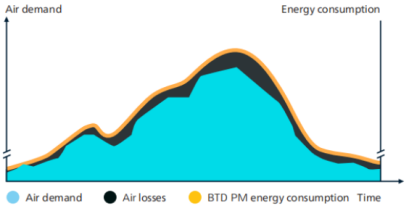

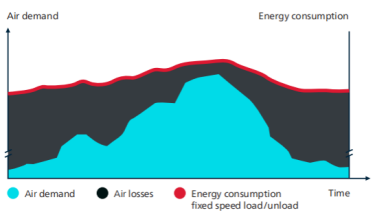

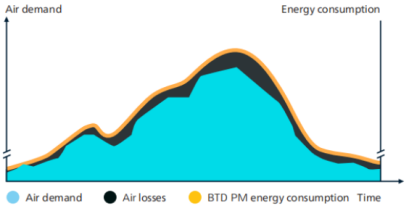

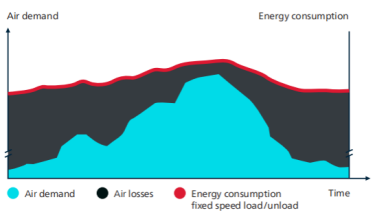

In almost every production environment, air demand fluctuates

In almost every production environment, air demand fluctuates

depending on different factors (time of the day,  week or even month). Extensive measurements and studies of compressed air demand profiles show that many compressors have substantial variations in air demand. Only 8% of all installations have a more stable air demand. Tests prove that, even in this case, PM compressors save energy.

week or even month). Extensive measurements and studies of compressed air demand profiles show that many compressors have substantial variations in air demand. Only 8% of all installations have a more stable air demand. Tests prove that, even in this case, PM compressors save energy.

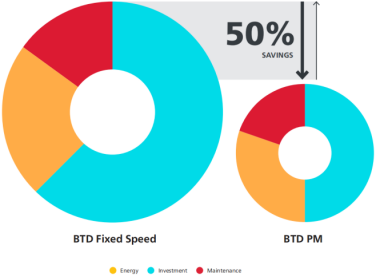

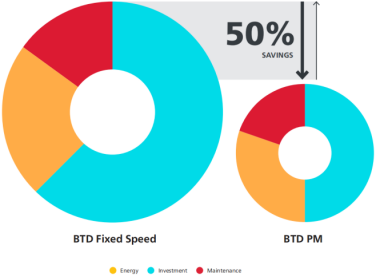

PM VSD for 50% average energy savings

PM VSD for 50% average energy savings

Bestrand’s PM Variable Speed Drive(VSD) technology closely matches the air demand by automatically adjusting the motor

speed. Combined with the innovative design of the

PM (Permanent Magnet) motor, this results in average energy

savings of 50% and an average reduction of 37% in the

life cycle cost of a compressor.

Why Bestrand choose PM VSD technology?

•On average 50% energy savings with an extensive fow range (20-100%).

•On average 50% energy savings with an extensive fow range (20-100%).

•Integrated Elektronikon® Touch controller controls

the motor speed and high-efficiency frequency inverter.

•No wasted idling times or blow-of losses during operation.

•Compressor can start/stop under full system pressure without the

need to unload.

•Eliminates peak current penalty during start-up.

•Minimizes system leakage due to a lower system pressure.

•EMC compliance to directives (2004/108/EG).

*Compared to fixed speed compressors, based on measurement

Performed by an independent energy audit agency.

Permanent Magnet Inverter Screw Air Compressor

In almost every production environment, air demand fluctuates

In almost every production environment, air demand fluctuates

depending on different factors (time of the day,  week or even month). Extensive measurements and studies of compressed air demand profiles show that many compressors have substantial variations in air demand. Only 8% of all installations have a more stable air demand. Tests prove that, even in this case, PM compressors save energy.

week or even month). Extensive measurements and studies of compressed air demand profiles show that many compressors have substantial variations in air demand. Only 8% of all installations have a more stable air demand. Tests prove that, even in this case, PM compressors save energy.

PM VSD for 50% average energy savings

PM VSD for 50% average energy savings

Bestrand’s PM Variable Speed Drive(VSD) technology closely matches the air demand by automatically adjusting the motor

speed. Combined with the innovative design of the

PM (Permanent Magnet) motor, this results in average energy

savings of 50% and an average reduction of 37% in the

life cycle cost of a compressor.

Why Bestrand choose PM VSD technology?

•On average 50% energy savings with an extensive fow range (20-100%).

•On average 50% energy savings with an extensive fow range (20-100%).

•Integrated Elektronikon® Touch controller controls

the motor speed and high-efficiency frequency inverter.

•No wasted idling times or blow-of losses during operation.

•Compressor can start/stop under full system pressure without the

need to unload.

•Eliminates peak current penalty during start-up.

•Minimizes system leakage due to a lower system pressure.

•EMC compliance to directives (2004/108/EG).

*Compared to fixed speed compressors, based on measurement

Performed by an independent energy audit agency.